5um Spherical Copper Powder ultrafine Cu China factory price

5um Spherical Copper Powder Ultrafine Cu China Factory Price

Specification:

| Code | B037-5 |

| Name | Spherical Copper Powder |

| Formula | Cu |

| CAS No. | 7440-50-8 |

| Particle Size | 5um |

| Purity | 99% |

| Morphology | Spherical |

| Appearance | copper red |

| Package | 100g,500g,1kg or as required |

| Potential applications | Conductive, wear-resistant, lubricating, alloy product materials, etc. |

Description:

Application of Spherical Copper powder ultrafine Cu powder:

1. Wear-resistant repair materials

Ultra-fine copper powder is very easy to combine with various metal materials such as iron and aluminum to form alloy materials. As a wear-resistant repair material, it can first fill the 0.508-25.4um roughness of modern machine tool processing metal surface and the processing deviation of about 5 microns This is what the modern machinery processing industry cannot achieve, which is required for precision wear-resistant instruments and equipment.

2. Conductive

In the electronics industry, ultra-fine copper powder is the best conductive composite material, electrode material, the terminal and internal electrodes of multilayer ceramic capacitors, and electronic packaging pastes for electronic components. Compared with ordinary copper powder, it will bring quality and performance. Great changes.

3. Catalyst

In the petrochemical industry, ultrafine copper and its alloy powders are used as catalysts with high efficiency and strong selectivity. They can be used as synthesis catalysts in the process of carbon dioxide and hydrogen synthesis of methanol, acetylene polymerization, and acrylonitrile hydration.

4. Wear-resistant materials

In the mechanical brake industry, copper powder is an excellent wear-resistant material. It can be used with various non-metallic materials to produce extremely high-quality friction parts, such as brake bands, clutch discs, etc.

5. Functional coatings and sterilization sanitary coatings.

6. Electromagnetic shielding

Solve the electromagnetic shielding and conductive problems of ABS, PPO, PS and other engineering plastics and wood. The production of electromagnetic shielding engineering materials has the advantages of low cost, easy coating, good electromagnetic shielding effect, and wide application range. It is especially suitable for engineering plastics. The electronic products of the housing are resistant to electromagnetic wave interference.

Storage Condition:

Spherical Copper Powder Ultrafine Cu Powder should be stored in sealed, avoid light, dry place. Room temperature storage is ok.

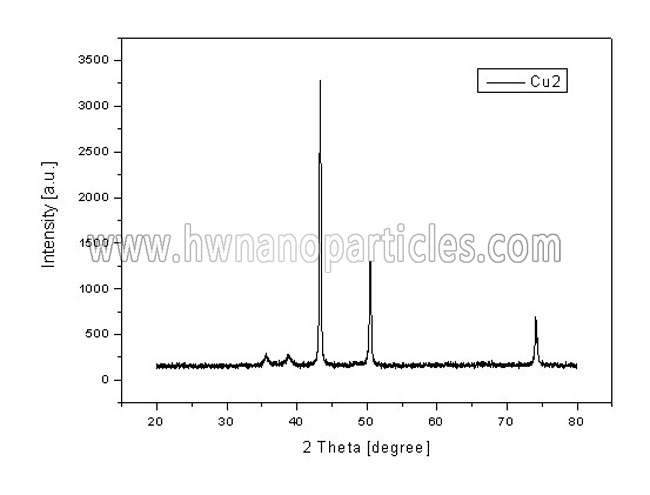

SEM & XRD :

Send your message to us:

-

Phone

-

E-mail

-

WhatsAPP

-

Wechat

Wechat

-

Skype

Skype