Gas sensor material Tin oxide nano powder, SnO2 nanoparticle price

|

||||||||||||||||

|

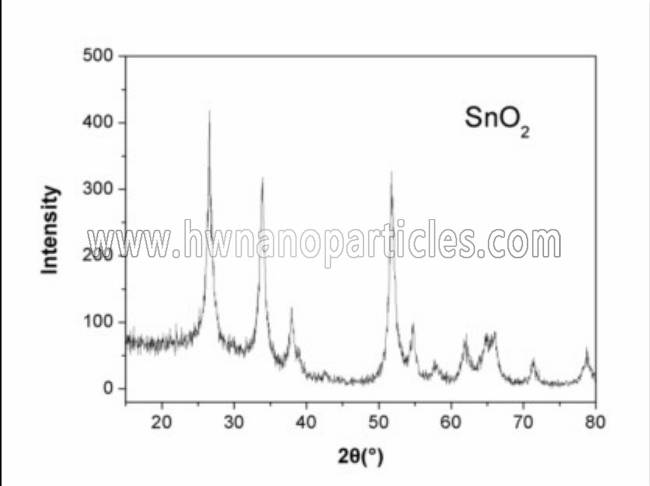

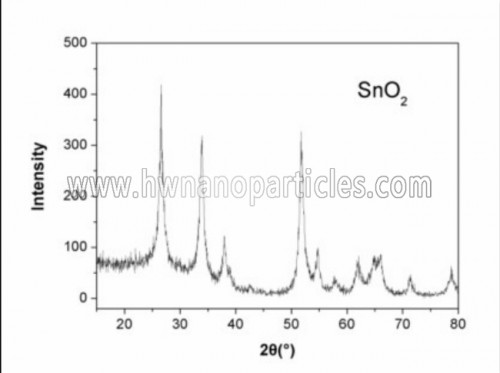

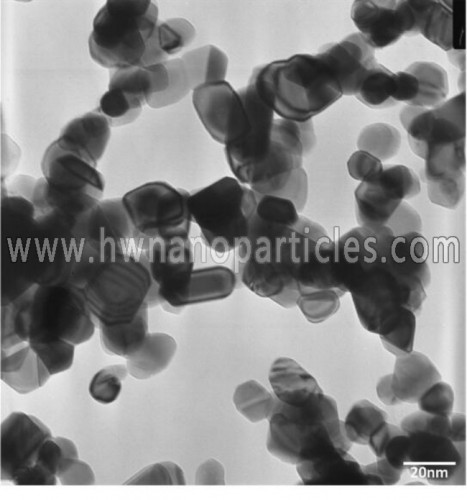

Note: according to user requirements of nano particle can provide different size products. Product performance Melting point 1630 ℃, boiling point of 1800 ℃.It is an excellent transparent conductive material, and it was the first transparent conductive material to be put into commercial use. It has reflection infrared radiation characteristics, small size effect, quantum size effect, surface effect and macro quantum tunneling effect. Application direction SnO2 nano powder is an important semiconductor sensor material, the gas sensor made by it with high sensitivity, widely used for the detection and prediction of various combustible gas, environmental pollution gas, industrial exhaust gas and harmful gas. The moisture sensor based on SnO2 has been applied in improving indoor environment, precision instrument room, library, art museum and museums. As the earliest commercialized gas sensor, tin oxide gas sensors have high sensitivity, Fast response speed, low cost and other excellent performance, it still occupies the mainstream position of the gas sensor market. It is widely used in the detection of combustible gases such as natural gas, liquefied petroleum gas, C2H2 and H2. With the improvement of people's living standards and increasing attention to environmental pollution issues, the detection objects of gas sensors have expanded to CO, H2S, NH3, NO2, NO, SO2 and other toxic gases. At present, there are divergent opinions on the gas-sensing mechanism of materials. The main representative ones are the energy level generation theory, the surface space charge layer model, the grain boundary barrier model, and the dual function model. Among them, the dual function model can better explain the current grain size. The reason why the gas sensitivity of the material is significantly improved when it is reduced below a certain critical value. Storage conditions This product should be stored in dry, cool and sealing of the environment, can not be exposure to air, in addition should avoid the heavy pressure, according to ordinary goods transportation. |