Nano Silica Powder for Epoxy Coating Use SiO2 Nanoparticle

Nano Silica Powder for Epoxy Coating Use SiO2 Nanoparticle

Specification:

| Code | M602,M606 |

| Name | Silica/Silicon dioxide/silicon oxide nanoparticles |

| Formula | SiO2 |

| CAS No. | 60676-86-0 |

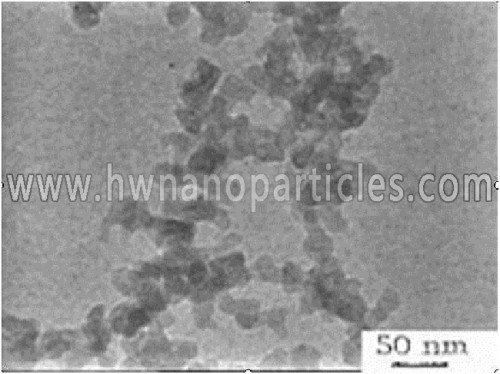

| Particle Size | 20nm |

| Purity | 99.8% |

| Appearance | white powder |

| MOQ | 10kg/25kg |

| Package | 10kg/25kg/30kg |

| Potential applications | Coating, paint, catalyst, antibacterial, lubricant, rubber, binder, etc.. |

Description:

1. For its own small size, SiO2 nanopowder can effectively fill the micro-cracks and pores formed by local shrinkage during the curing process of epoxy resin, reduce the diffusion path of corrosive media, and enhance the shielding and protective performance of the coating;

2. For its high hardness, silica nanoparticle increases the hardness of the epoxy resin, thereby enhancing the mechanical properties.

In addition, adding an appropriate amount of nano silicon oxide particles can also increase the interface bonding strength of the epoxy coating and extend the service life of the coating.

Nano silica is an inorganic non-metallic material with excellent heat and oxidation resistance. Its molecular state is a three-dimensional network structure with [SiO4] tetrahedron as the basic structural unit. Among them, oxygen and silicon atoms are directly connected by covalent bonds, and the structure is strong, so it has stable chemical properties, excellent heat and weather resistance, etc.

Nano silicon dioxide mainly plays the role of anti-corrosion filler in epoxy coating. On the one hand, nano SiO2 can effectively fill the micro-cracks and pores generated in the curing process of epoxy resin, and improve the penetration resistance; on the other hand,the functional groups of nano silica and epoxy resin can form physical/chemical cross-linking points through adsorption or reaction, and introduce Si—O—Si and Si—O—C bonds into the molecular chain to form a three-dimensional network structure to improve coating adhesion. In addition, the high hardness of nano SiO2 can significantly enhance the wear resistance of the coating, thereby prolonging the service life of the coating.

Storage Condition:

SiO2 nanoparticles nano silica powder should be well sealed stored in dry and cool place.

Send your message to us:

-

Phone

-

E-mail

-

WhatsAPP

-

Wechat

Wechat

-

Skype

Skype