Nanotechnology can make many traditional products “renewed”. The use of nano-modification technology in the production of traditional materials can improve or obtain a series of functions. Nano ceramic coating is a multifunctional composite coating composed of modified ceramic materials and nano materials, which has significant thermal insulation effect and excellent corrosion resistance. Among them, the addition of nano materials has many characteristics, such as high-density sealing and anti-corrosion performance of ceramic materials, anti-fouling and self-cleaning, hardness, toughness, wear resistance, high temperature resistance, antistatic property, UV resistance, heat insulation and many other properties are markedly improved.

Nano ceramic powders have been widely used in high-tech fields such as fine ceramics, functional ceramics, bioceramics and fine chemical materials because of their excellent mechanical, optical and electrical properties, and have become the cornerstone of today’s development of high-tech materials.

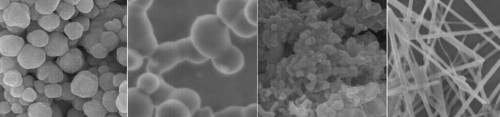

The following introduces several nano powders used in ceramics:

1. Nano silicon carbide (SiC) and silicon carbide whiskers

Silicon carbide nano powders and whiskers have excellent properties, such as high strength, hardness, elastic modulus, light weight, heat resistance, corrosion resistance, and chemical stability. The application of silicon carbide to ceramic composite materials can significantly improve the original brittleness of ceramics, and also improve its high-temperature heat resistance, and can be used as high-temperature corrosion-resistant chemical reactor materials.

2. Nano silicon nitride (Si3N4)

2.1. Manufacture of precision structural ceramic devices.

2.2. Surface treatment of metals and other materials.

2.3. Used as modifier to improve the performance of high wear-resistant rubber.

2.4. Silicon-based nanopowders can enhance the electrical conductivity of nylon and polyester.

2.5. Nano silicon nitride modified plastic optical cable reel.

3. Nano titanium nitride (TiN)

3.1. Nano titanium nitride in PET packaging bottles and plastic packaging materials

a. Reduce the temperature of thermoplastic molding and save energy by 30%.

b. Shade the yellow light, improve the brightness and transparency of the product.

c. Increase the heat distortion temperature for easy filling.

3.2. Improve the performance of PET engineering plastics.

3.3. The high thermal emissivity coating is used in high temperature furnaces and kilns for energy saving and military industries.

3.4. Titanium nitride modified functional fabric.

4. Nano titanium carbide (TiC)

4.1. Widely used in the manufacture of wear-resistant materials, cutting tools, molds, smelting metal crucibles and many other fields.

4.2. The hardness of nano titanium carbide(TiC) is comparable to that of artificial diamond, which greatly improves the grinding efficiency, grinding accuracy and surface finish.

4.3. Metal surface coating material.

5. Nano-zirconia/zirconium dioxide (ZrO2)

ZrO2 nano powder is an important raw material for the preparation of special ceramics, which can be used to prepare a variety of structural and functional ceramics.

5.1. Phase transformation toughened ceramics

The brittleness of ceramic materials limits its application development, and nano ceramics are a very important way to solve the issue. Experiments show that the ceramics can be toughened by the use of ZrO2 tetragonal phase to monoclinic phase to generate microcracks and residual stress. The transition temperature can drop below room temperature when the ZrO2 particles are at the nanoscale. Therefore, nano ZrO2 can significantly improve the room temperature strength and stress intensity factor of ceramics, thereby multiplying the toughness of ceramics.

5.2. Fine ceramics

Nano zirconia can significantly improve the room temperature strength and stress intensity factor of ceramics, thereby multiplying the toughness of ceramics. The composite bioceramic material prepared by nano ZrO2 has good mechanical properties, chemical stability and biocompatibility, and is a kind of composite bioceramic material with great application prospects.

5.3. Refractory

Zirconia has a high melting point, low thermal conductivity and stable chemical properties, so it is often used as a refractory material. The advantages of the refractory material prepared with nano zirconia are more significant, such as high temperature resistance (use temperature can reach 2200℃), high strength, good thermal insulation performance and excellent chemical stability, and it is mainly used in the environment with operating temperature above 2000℃.

5.4. Wear-resistant material

Adding 5% nano scale Al2O3 powder to conventional Al2O3 ceramics can improve the toughness of the ceramics and reduce the sintering temperature. Due to the superplasticity of nano-Al2O3 powder, it solves the shortcomings of low temperature brittleness that limit its application range, so it is widely used in low temperature plastic alumina ceramics. Can be applied to functional ceramics, structural ceramics, transparent ceramics, textile ceramics.

Nano zinc oxide is an important raw material of ceramic chemical flux, especially in building ceramic wall and floor tile glaze and low temperature magnetic material.

Used as flux, opacifier, crystallizer, ceramic pigment, etc.

Preparation of ceramic capacitor dielectric materials

Nanocrystalline composite ceramics

Glass ceramic coating

High toughness ceramic material

9. Nano barium titanate BaTiO3

9.1. multilayer ceramic capacitors(MLCC)

9.2. Microwave dielectric ceramics

9.3. PTC thermistor

9.4. Piezoelectric Ceramics

The above nanomaterials, including but not limited to nano silicon carbide powder, silicon carbide whiskers, nano titanium nitride, nano titanium carbide, nano silicon nitride, nano zirconium dioxide, nano magnesium oxide, nano alumina, nano zinc oxide, nano barium titanate, botha are available by Hongwu Nano. If you would like to have further info, please don’t hesitate to contact us now!

Post time: Apr-07-2022