Ifekthri inikezela nge-HW-D500C SiCNWs i-silicon carbide nanowires

Ifekthri inikezela nge-HW-D500C SiCNWs i-silicon carbide nanowires

Ukucaciswa:

| Ikhodi | D500C |

| Igama | I-silicon carbide nanowires |

| Ifomula | Ama-SICNWs |

| Inombolo ye-CAS. | 409-21-2 |

| Ububanzi&Ubude | D <500nm L 50-100um |

| Ubumsulwa | 99% |

| Uhlobo lweCrystal | cubic |

| Ukubukeka | grey green |

| Iphakheji | 10g, 50g, 100g, 200g noma njengoba kudingeka |

| Izinhlelo zokusebenza ezingaba khona | Izinto eziyinhlanganisela eziqinisiwe neziqinisiwe, izinhlanganisela ze-Metal matrix kanye ne-ceramic matrix eziqiniswe futhi zaqiniswa yi-silicon carbide nanowires zisetshenziswe kabanzi emishinini, embonini yamakhemikhali, ekuvikelweni kwezwe, amandla, ukuvikelwa kwemvelo nakweminye imikhakha. |

Incazelo:

Izici ezibonakalayo ze-silicon carbide nanowire:

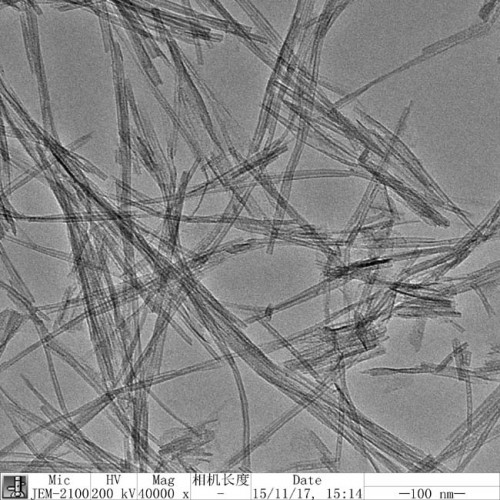

I-Cubic crystal, okuwuhlobo lwekristalu olufana nedayimane.Kuyikristalu enohlangothi olulodwa olunamandla aphezulu kanye nokuma kwentshebe.Inezici eziningi ezinhle kakhulu zemishini ezifana namandla aphezulu kanye ne-modulus ephezulu, okungenye yezinto ezinhle kakhulu eziqinisayo neziqinisayo.

Izakhiwo zamakhemikhali ze-silicon carbide nanowires:

Ukumelana nokugqoka, ukumelana nokushisa okuphezulu, ukumelana nokushaqeka okukhethekile, ukumelana nokugqwala, ukumelana nemisebe.

Izikhombisi-ndlela eziyinhloko ze-silicon carbide nanowires:

1.Izinhlanganisela ze-SIC nanowires/ceramic matrix:SIC/TIC/WC/ALN/SI3N4/TIN/AL2O3/ZRO2/ZRB2 njll

2.SIC izinhlanganisela ze-nanowires/metal matrix:AL/TI/NI njll

3.Izinhlanganisela ze-SIC nanowires/polymer: Inayiloni/inhlaka/irabha/ipulasitiki njll.

Ukuhlakazeka kanye nenani elingeziwe le-SiC Nanowires:

Ukuhlakazeka kanye nenani elingeziwe le-SiC Nanowires (ngokwereferensi kuphela)

Imithombo yezindaba enconyiwe yokuhlakazwa: amanzi akhishiwe, amanzi acwebile, i-anhydrous ethanol, i-ethylene glycol

I-dispersant enconyiwe:I-Polyethylene imine (PEI), i-nonionic polyacry lamide (PAM), i-sodium pyrophosphate (SPP), i-twain 80, i-silicon compound coupling agent, i-polyethylene glycol, i-sodium hexametaphosphate, i-sodium carboxymethyl cellulose (CMC), njll.

Ezingxenyeni ezijwayelekile ze-ceramic matrix, ama-silicon carbide nanowires angaphansi kuka-10wt% ngokuvamile ayengezwa.Ngokomkhuba wokuhlola, ukuphakama kwenani elengezayo akukona ukuthi kungcono kakhulu, kuhlobene nempahla eluhlaza, usayizi wezinto ezibonakalayo, izinga lokushisa le-sintering, inani elizwakalayo lokungeza lingathola umphumela omuhle kakhulu wokuqina.

Ngemuva kokuxuba i-SiC nanowire slurry ehlakaziwe kanye ne-ceramic powder, qhubeka uhlakaza amahora angu-1-12.Kunconywa ukuhlakazeka kogayo lobuhlalu noma indlela yokunyakazisa ngomshini.Indlela yokugaya ibhola kulula ukubangela ukuthi ama-nanowires aphule.

Uma ukuxutshwa kwe-SiC nanowires nezinto ze-matrix kungekuhle kangako, i-sodium hexametaphosphate ka-1% wesisindo se-SiCNW (noma inani elincane le-isopropanol/ethanol) ingngezwa njengesihlakazeka ukuze kuthuthukiswe ukufana kokuxuba.

Ngemuva kokuhlakazeka, ukoma kanye nokuphelelwa amandla kwamanzi kufanele kwenziwe ngokushesha.Thela i-slurry emkhunjini enendawo enkulu ukuze uyisakaze ibe mncane, futhi ukwandise indawo izokhuphuka futhi ikhiphe amanzi kalula.Kubaluleke kakhulu ukugwema ukuchithwa kwezinto eziluhlaza phakathi kwe-nanowires kanye ne-matrix.Izinga lokushisa elinconywayo lokumisa liyi-110-160 ℃.

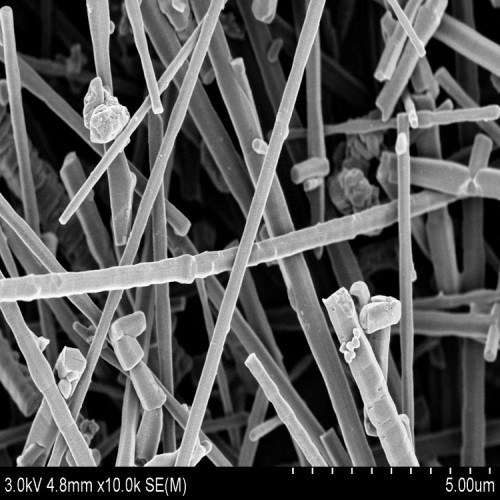

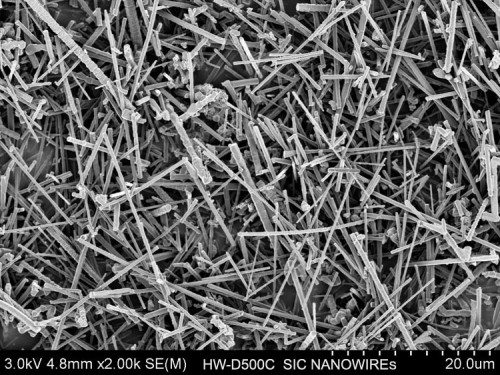

I-SEM: