I-CMP isebenzise i-Silicon Dioxide Nanoparticle Nano SiO2 ye-chemical polishing

I-CMP isebenzise i-Silicon Dioxide Nanoparticle Nano SiO2 ye-chemical polishing

Inkcazo:

| Igama | I-Silicon Dioxide / i-Silica / i-Silicon oxide Nanopowders |

| Ifomula | SiO2 |

| Uhlobo | I-Hydrophobic, i-hydrophilic |

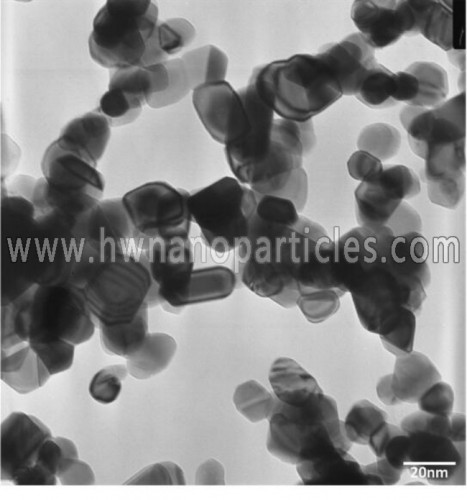

| Ubungakanani beNcam | 20nm |

| Ubunyulu | 99.8% |

| Imbonakalo | Umgubo omhlophe |

| Iphakheji | 20kg/30kg ngengxowa/umphanda |

| Usetyenziso olunokwenzeka | Ukugquma okungangenwa ngamanzi, ukupolisha, irabha, i-ceramic, ikhonkrithi, ipeyinti, ukuzicoca, i-antibacterial, i-catalyst, i-binder, i-lubricity, njl. |

Inkcazo:

Kutheni i-silicon dioxide nano powder ingasetyenziselwa i-CMP?

I-Nano-silica inexabiso eliphantsi ngokwentelekiso, kwaye i-dispersibility entle, ukuqhawuka koomatshini, ukomelela okuphezulu kunye nokuncamathela, ukwakheka kwefilimu elungileyo, ukungeneka okuphezulu, imozulu ephezulu kunye nokunganyangeki, ubungakanani bamasuntswana amancinci, ubulukhuni.Ikwanayo neengenelo zokumodareyitha, i-viscosity ephantsi, i-adhesion ephantsi, kunye nokucoca ngokulula emva kokupolisha.Yiyo loo nto iyinto yokupholisha itekhnoloji yeCMP esebenza kakuhle.

I-SiO2 i-nano particle isoloko isetyenziselwa ukucwangciswa ngokuchanekileyo kwesinyithi, isafire, i-silicon ye-monocrystalline, i-glass-ceramics, ityhubhu yesikhokelo esikhanyayo kunye nezinye iindawo.Ubungakanani be-nano silicon oxide bungaphantsi kwe-100nm, enendawo enkulu yendawo ethile, i-dispersibility ephezulu kunye ne-permeability, ngoko ke umaleko womonakalo kumphezulu we-workpiece epholisiweyo incinci kakhulu;ukongeza, ubunzima be-silica nanoparticle bufana ne-silicon wafers.Ke ngoko, ikwahlala isetyenziselwa ukupolisha ii-silicone wafers zesemiconductor.

Iingenelo ze-nano SiO2 powder kwisicelo se-CMP:

1. Ukupholisa kukusetyenziswa kwe-nanoparticles efanayo yeSiO2 kunye nezinye izinto, ezingayi kubangela umonakalo womzimba kwiindawo ezicutshungulwayo, kwaye isantya sikhawuleza.Ukusetyenziswa kweengqungquthela ezifana ne-colloidal silica kunye neyunifomu kunye nobukhulu beengqungquthela ezinkulu kunokufezekisa injongo yokupholisa ngesantya esiphezulu.

2. Ayina corrode izixhobo kwaye inomsebenzi ophezulu wokhuseleko.

3. Ukufezekisa ukucutshungulwa kokusila okuphezulu.

4. Ukunciphisa ngokufanelekileyo i-scratches ebusweni emva kokupholisa kunye nokunciphisa ubuninzi bomhlaba emva kokupholisa.

Imeko yoGcino:

I-Silicon dioxide (SiO2) i-nanopowders kufuneka igcinwe itywinwe, igweme ukukhanya, indawo eyomileyo.Ukugcinwa kobushushu begumbi kulungile.

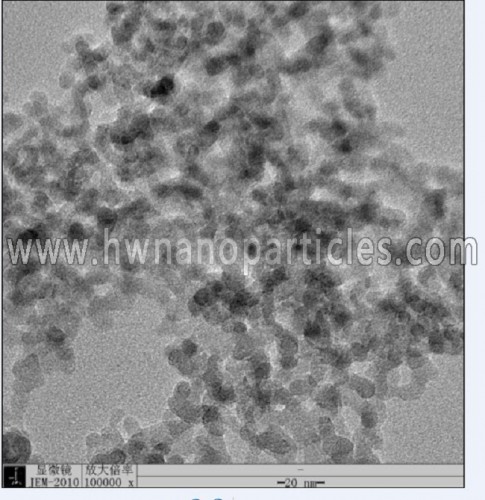

I-SEM: